What are Semiconductor Cleanrooms? Precision Engineering for Advanced Manufacturing

When manufacturing semiconductors, even tiny particles can cause defects that ruin entire production runs. That’s why semiconductor cleanrooms aren’t just clean spaces—they’re precision-engineered environments that control every variable that could impact your production. Think of them as protective chambers where your manufacturing processes can operate without interference from the outside world.

Building Contamination-Free Manufacturing Environments

Semiconductor cleanrooms control three main variables that traditional facilities can’t manage: air purity, environmental stability, and static electricity. Air filtration systems cycle the entire room’s atmosphere multiple times per hour through specialized filters, while temperature and humidity controls maintain conditions within fractions of a degree.

The real challenge comes from balancing cleanroom design systems with your production workflow. Equipment generates heat, personnel create particles, and chemical processes release vapors. Managing these competing forces while maintaining production schedules requires integrated mechanical systems designed specifically for semiconductor applications.

ISO Classification Standards for Semiconductor Applications

ISO classifications determine the maximum particle count allowed in your cleanroom, with lower numbers meaning cleaner environments. Semiconductor applications typically require ISO 4 or ISO 5 classifications – among the strictest standards in manufacturing. The classification you need depends on your specific processes:

Wafer Fabrication Areas:

Demand the highest cleanliness levels where circuits are actually created.

Assembly Operations:

Can often function at ISO 6 or ISO 7 standards with less stringent requirements.

Packaging Processes:

May operate effectively at ISO 7 or ISO 8 classifications for final product preparation.

Environmental Parameters for Semiconductor Production

Environmental control determines whether your semiconductor processes produce quality chips or expensive failures. Temperature fluctuations cause materials to expand and contract, throwing off the precise alignments your equipment needs for accurate circuit creation.

Humidity creates two problems: too much moisture contaminates surfaces, while too little generates static electricity that can fry your circuits. Vibration from nearby equipment or building movement disrupts the precision tools that create features smaller than anything visible under normal microscopes.

Advanced Infrastructure for Semiconductor Cleanrooms

Semiconductor facilities need infrastructure that goes beyond standard cleanroom requirements. Your manufacturing equipment generates heat, chemicals, and vibrations that standard HVAC systems can’t handle, while your processes demand stability that typical construction can’t provide.

HEPA and ULPA Filtration Systems

Standard HEPA filters aren’t enough for semiconductor manufacturing – you need advanced filtration that catches particles smaller than what basic systems can handle. These filtration systems protect your most sensitive processes from contamination that could destroy entire wafer batches:

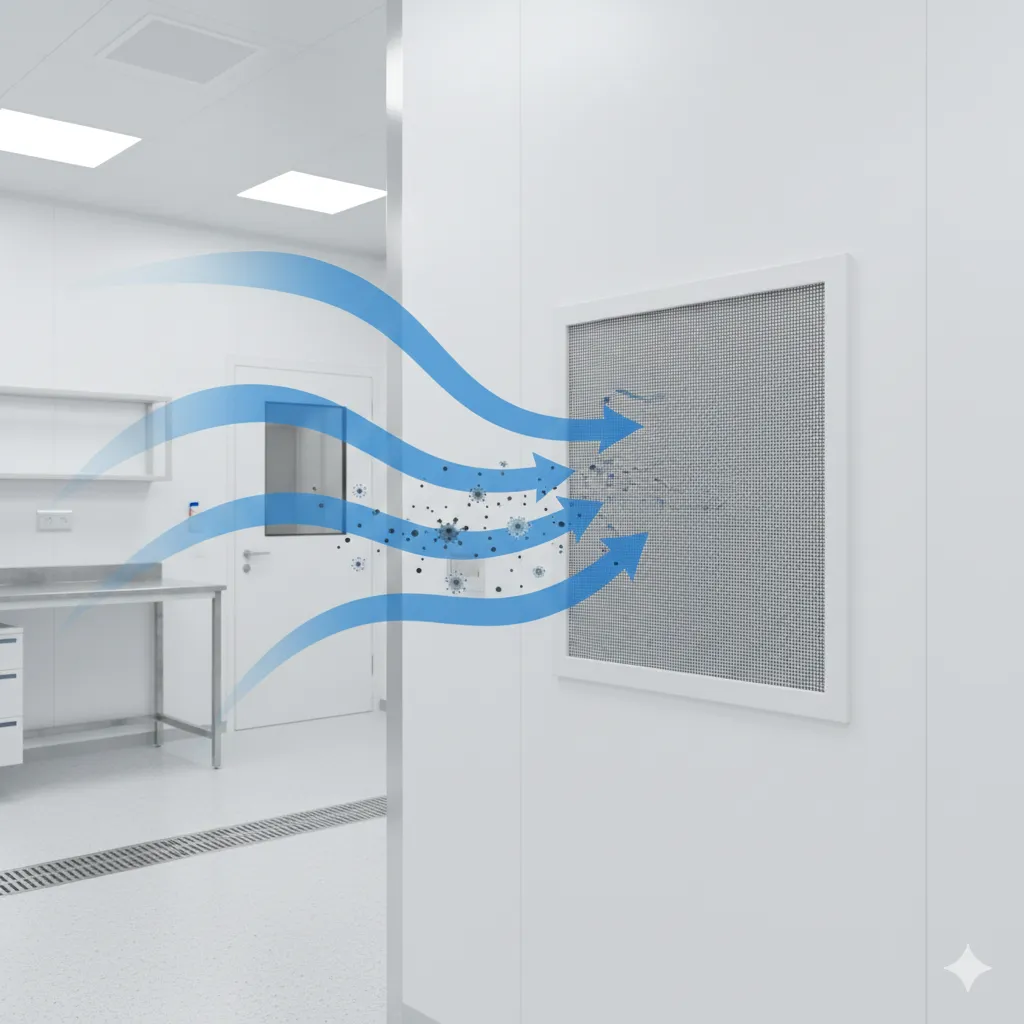

Fan Filter Units

Distribute clean air across work surfaces in patterns that sweep contaminants away from production areas.

HEPA and ULPA Filtration Systems

Standard HEPA filters aren’t enough for semiconductor manufacturing – you need advanced filtration that catches particles smaller than what basic systems can handle. These filtration systems protect your most sensitive processes from contamination that could destroy entire wafer batches:

Precision Climate Control Technologies

Temperature swings ruin semiconductor processes by causing materials to expand and contract at different rates, throwing off the precise alignments your equipment needs. Humidity problems create static electricity that can fry circuits or cause moisture contamination that destroys wafers.

Digital Direct Control systems automatically monitor and adjust environmental conditions, catching problems before they impact production. These systems integrate cooling, heating, and humidity control to maintain the stable conditions your processes demand while reducing energy waste from overcompensating systems.

Contamination Prevention Infrastructure

Personnel bring contamination into cleanrooms on their clothing, skin, and hair – even after gowning procedures. Without proper contamination barriers, a single person entering your production area can introduce enough particles to ruin an entire shift’s production:

Cleanroom Air Showers:

Blast personnel with filtered air before entry, removing particles that gowning procedures miss.

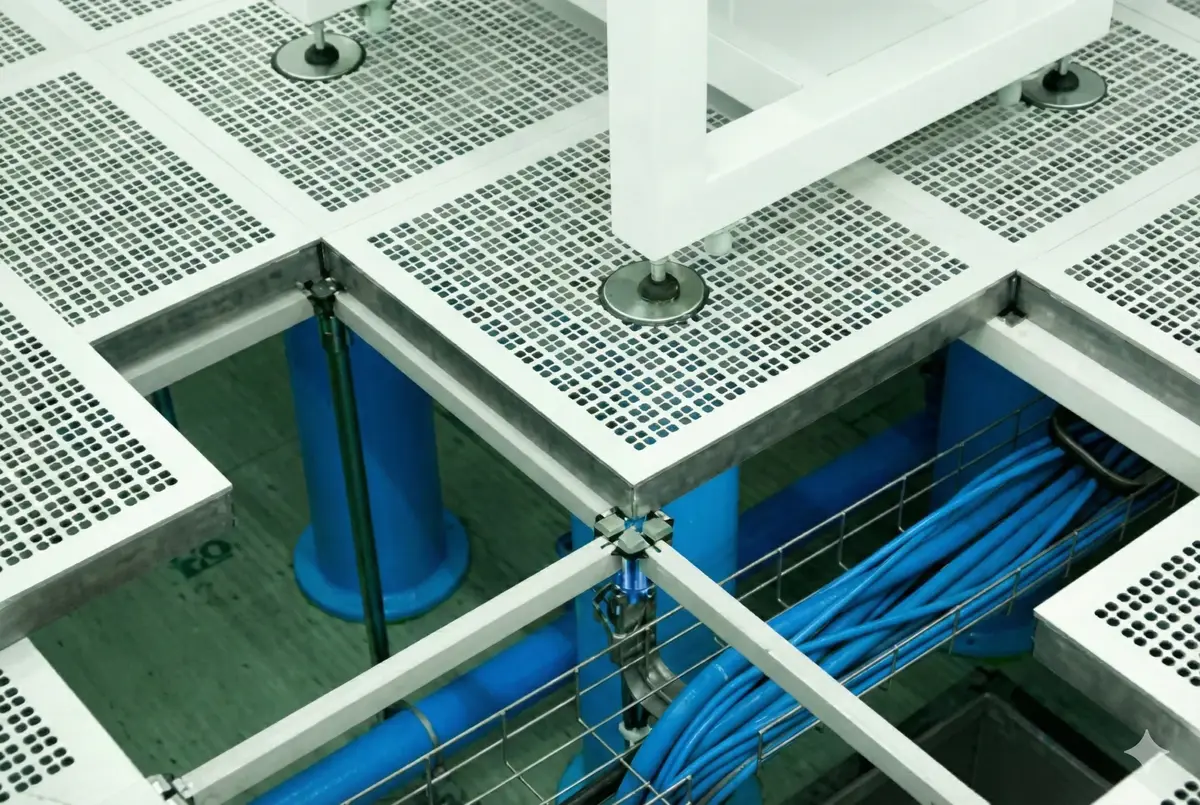

Raised Cleanroom Flooring:

Keep utility maintenance and contamination-generating activities away from your production level.

Material Transfer Systems:

Prevent contamination during equipment and supply movement between different cleanliness zones.

Operational Excellence in Semiconductor Cleanrooms

Your cleanroom infrastructure works best when your team has clear, practical procedures to follow. Well-designed protocols help personnel maintain cleanliness standards while keeping production moving without unnecessary delays.

Personnel Protocols and Training Standards

Production schedules create pressure to cut corners on gowning procedures, but shortcuts in cleanroom protocols can contaminate entire production runs. Proper training helps teams understand why each step matters and how to maintain cleanliness standards even under deadline pressure.

Gowning sequences also prevent contamination transfer from outside environments to production areas. Real-time particle monitoring shows immediately when procedures aren’t working, allowing quick corrections before contamination spreads throughout the facility.

Material Handling and Equipment Management

Moving supplies and equipment into cleanrooms without bringing contamination requires specialized transfer systems. Standard doors and loading procedures introduce particles that can shut down production lines for hours while contamination is cleared:

Pass-Through Chambers:

Create barriers that prevent contamination during material movement between areas with different cleanliness zones.

Clean Room Doors:

Incorporate interlocking mechanisms that maintain pressure differentials and prevent simultaneous opening.

Equipment Maintenance Protocols:

Keep maintenance activities from contaminating production areas while repairs happen.

Precision Environments: Your Partner in Cleanroom Excellence

Precision Environments designs and builds semiconductor cleanrooms with over 35 years of controlled environment experience. Our modular cleanroom systems adapt as manufacturing processes evolve while maintaining the contamination control semiconductor production demands. Call (513) 847-1510 or visit our Cincinnati office to discuss your semiconductor cleanroom project requirements.

FAQ

Why do semiconductors need a cleanroom?

Semiconductors need cleanrooms because manufacturing processes create circuit patterns smaller than particles invisible to the naked eye, making contamination control the difference between profitable production and costly failures.

How clean is a cleanroom for semiconductors?

Semiconductor cleanrooms achieve cleanliness levels that allow only dozens of particles in spaces where typical environments contain millions, typically operating at ISO Class 4 or Class 5 standards.

What level is a cleanroom for semiconductors?

Semiconductor cleanroom levels typically range from ISO Class 4 for wafer fabrication areas to ISO Class 6 or Class 7 for assembly and packaging operations, depending on the specific manufacturing processes involved.